In printing, coatings are thin layers added on top of paper or packaging. They make the surface look better and protect it from damage. A coating can keep colors bright, stop scratches, and give the product a smooth finish.

The main purpose of coatings is:

- To protect the print from wear and tear

- To improve the look and feel

- To make the product last longer

Using a coating is important if you want your printed material to look professional and stay safe during handling or shipping.

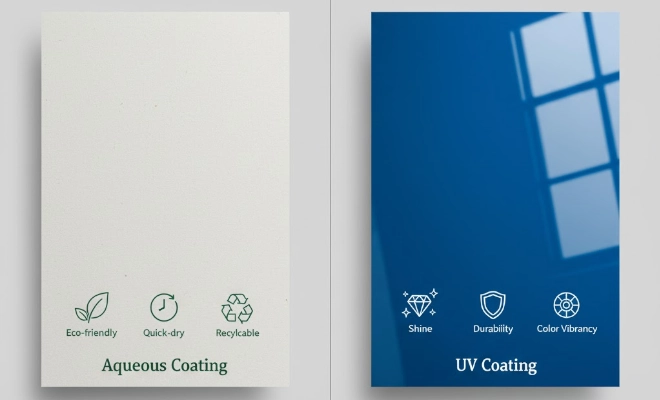

Among many options, Aqueous Coating and UV Coating are two of the most popular choices. Both give protection and shine, but they work in different ways.

What is Aqueous Coating?

Aqueous coating is a clear, water-based layer added on top of printed materials. It makes the surface smooth, protects the print from scratches, and gives it a polished look. Printers use it because it is fast-drying, safe, and cost-effective.

Aqueous coating is applied in-line during the printing process. This means it is added right after the ink is printed, without needing extra steps later. It saves time and makes the process more efficient. It is also eco-friendly and recyclable. Since it is water-based, it does not harm the environment and is safe to use on packaging.

Common Finishes

You can choose different finishes:

- Gloss: bright and shiny finish that makes colors pop

- Matte: smooth, non-shiny finish for a soft look

- Satin/Dull: a finish that is neither too shiny nor too matte

What is UV Coating?

UV coating is a clear liquid layer applied to printed materials to make them stronger and shinier. One of the main benefits of UV coating is its durability. It protects prints from scratches and fingerprints while keeping the surface smooth and eye-catching.

This coating is made from a UV-curable liquid. When applied, it creates a strong layer that gives prints a glossy appearance. After printing, the coating is exposed to ultraviolet (UV) light. The light cures the coating instantly, making it hard and fast.

Available Finishes

UV coating is not just glossy. It also comes in:

- Gloss: very shiny, bold finish

- Matte: smooth, non-shiny finish

- Textured: special patterns or raised effects for unique looks

Key Differences Between Aqueous and UV Coating

| Feature | Aqueous Coating | UV Coating |

| Base Material | Water-based | Polymer-based |

| Curing Method | Air-dried or heat-dried | UV light curing |

| Finish Options | Gloss, matte, satin | High-gloss, matte, textured |

| Environmental Impact | Eco-friendly, recyclable | Less eco-friendly, VOCs may be present |

| Durability | Moderate | High durability, scuff and scratch resistant |

| Cost | Lower | Higher |

| Drying Time | Quick, but slower than UV | Instantly with UV exposure |

| Paper Compatibility | Most common paper stocks | Best on coated or gloss stocks |

Pros and Cons

Aqueous and UV coatings both improve the look and protection of printed materials, but they have different strengths and limits.

- Aqueous coating is eco-friendly and recyclable, making it a good choice for sustainable printing. It dries quickly, is cost-effective, and helps resist fingerprints and smudges. However, it is less durable than UV coating, does not offer the same high gloss, and cannot achieve all specialty finishes.

- UV coating gives prints an extremely glossy and vibrant look. It is very durable, long-lasting, and works well for photo-heavy prints or premium packaging. However, it is more expensive, may not always be recyclable, and if applied incorrectly, the coating can crack when folded.

When to Use Aqueous or UV Coating

Aqueous coating is a great choice for everyday printing needs. Since it dries fast, it is ideal for projects that need a quick turnaround. Many eco-conscious brands prefer it because it is water-based, recyclable, and safe for the environment.

On the other hand, UV coating is best for projects that need a high-end look and strong durability. Its glossy finish makes colors more vibrant and keeps prints protected for a long time.

Common Applications in Packaging and Printing

Both aqueous and UV coatings are widely used in printing and packaging to protect materials and improve their look.

- Aqueous Coating: Commonly used for magazines, textbooks, flyers, and general packaging.

- UV Coating: Often applied to business cards, product packaging, premium catalogs, and promotional materials.

Conclusion

Aqueous and UV coatings both add value to printed and packaged materials, but in different ways. Choosing the right option depends on the balance you want between eco-friendliness, durability, and visual impact. Understanding these differences helps you match the coating to your project’s needs while enhancing overall quality.