Embossing and debossing are printing techniques that create a raised or pressed effect on paper, cardboard, or other materials. These methods add texture and depth, making designs visible and stand out.

In packaging and branding, they are used to highlight logos, names, or patterns, giving products a professional and premium look. This guide explains what embossing and debossing are, how they work, and where they are commonly used.

What is Embossing?

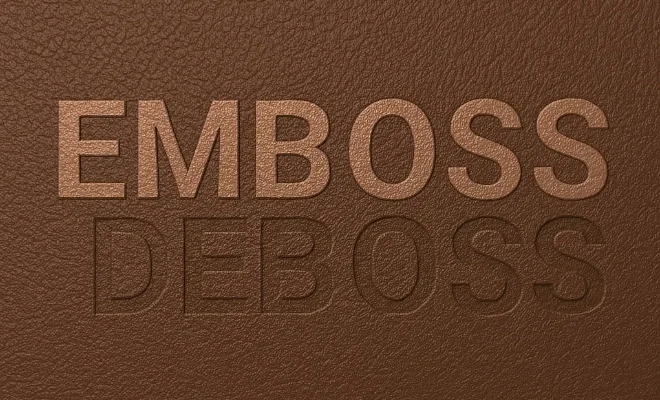

Embossing is a printing process that creates a raised design on the surface of paper, cardboard, or other materials. It makes the design stand out visually and gives it a textured effect.

What is Debossing?

Debossing is the opposite of embossing. It creates a recessed or sunken design on the surface, pressing the artwork into the material for a subtle and elegant look.

Difference:

The key difference is that embossing creates a raised effect on the surface, while debossing creates an indented effect into the material.

How the Process Works

Embossing and debossing are performed using custom metal dies, which consist of a male die and a female die. Pressure is applied to press the material between these dies, creating either a raised or recessed effect.

These techniques can be applied without any ink (known as blind embossing or debossing) or combined with foil stamping or printing for added impact.

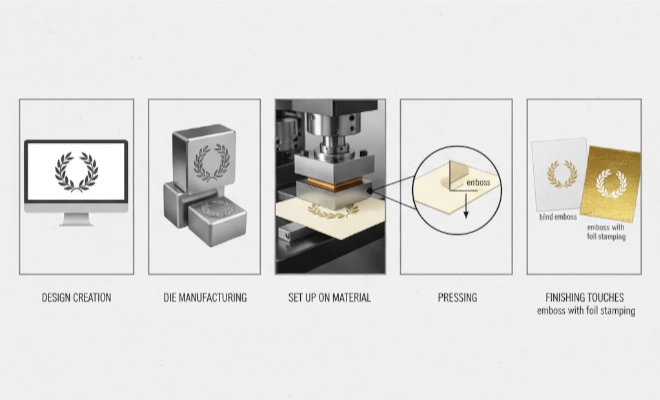

Steps in the Process:

- Design Creation: The artwork or logo is prepared digitally. This design will later be used to make the dies.

- Die Manufacturing: Two custom metal dies are created: a male die (raised) and a female die (recessed). These dies must fit together perfectly.

- Set up on Material: The dies are placed in a press with the material (such as paper, leather, or cardboard) positioned between them.

- Pressing: Pressure is applied so the dies press into the material. This creates either a raised (embossed) or sunken (debossed) impression.

- Finishing Touches: The design can be left plain (blind embossing/debossing) or combined with foil stamping, ink, or coatings for a more premium effect.

Types of Embossing and Debossing

- Blind Embossing/Debossing: The design is pressed without any ink or foil, creating a clean and simple look.

- Registered Embossing: The raised or recessed design is aligned with a printed or foiled area for more detail.

- Sculpted/Multilevel Embossing: Creates complex, layered, or 3D effects for a more textured and artistic finish.

- Combination Stamping: Combines embossing or debossing with foil stamping to add both depth and shine.

Benefits of Embossing and Debossing

- Embossing and debossing offer both tactile and visual impact, making designs more noticeable and engaging.

- They are often perceived as high-end and premium, which helps packaging stand out in the market.

- These techniques also enhance brand identity by adding depth and style to logos, patterns, or text.

- They also work well with other finishes like foil stamping or spot UV, creating a more unique and visible design.

Materials That are Used for Embossing and Debossing

- Paper: Paper is the most common choice as it embosses or debosses easily and gives a clean, sharp impression. It is great for business cards, invitations, and packaging.

- Cardstock: Thick cardstock is perfect for creating deeper impressions, making designs more stylish.

- Leather: Leather embossing or debossing adds a long-lasting effect, often used in luxury goods like fashion items and accessories.

- Fabric: Fabrics can be embossed or debossed to add texture and a decorative look, especially in the textile industry.

- Packaging materials: Many types of packaging materials can be embossed or debossed to enhance branding.

- Vinyl: It is durable and often used for labels, covers, or decor for a textured effect.

Should I Choose Embossing or Debossing?

The choice between embossing and debossing depends on the look and feel you want for your design. Embossing creates a raised effect that feels more tactile and visually appealing. It makes a good choice if you want to highlight logos, names, or special details. Debossing, on the other hand, creates an indented effect that looks subtle and elegant.

If your goal is to grab attention with texture, embossing works well. If you prefer an understated style, debossing is the better option. In some cases, brands even combine both with other finishes like foil stamping to achieve a premium look.

Conclusion

Embossing and debossing are two finishing techniques that add texture, depth, and style to designs. Both options enhance brand identity, make packaging unique, and create a premium feel. Choosing the right method depends on the style and impact you want, and these techniques ensure a professional finish.