Measuring a box may look simple, but it is very important for packaging and shipping. The right dimensions help you choose the correct box, avoid product damage, and save on shipping costs. By knowing how to measure length, width, and height properly, you can make sure your products fit well and stay safe during storage or delivery.

The Three Dimensions of a Box

It is important to understand that you have to measure the three dimensions of the box from the inside and not the outside. It can be measured by using a tape or ruler.

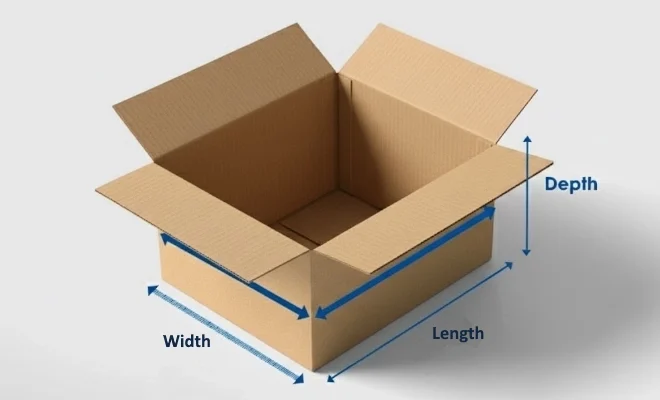

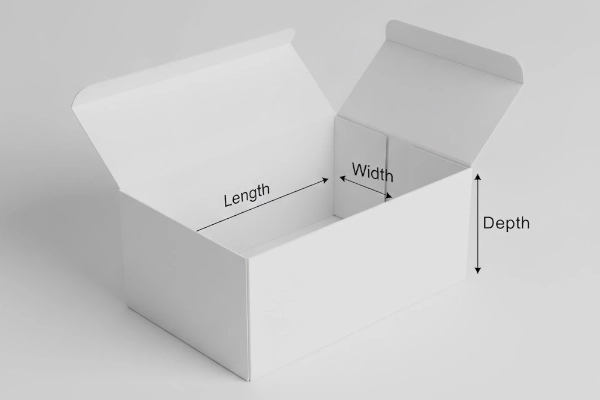

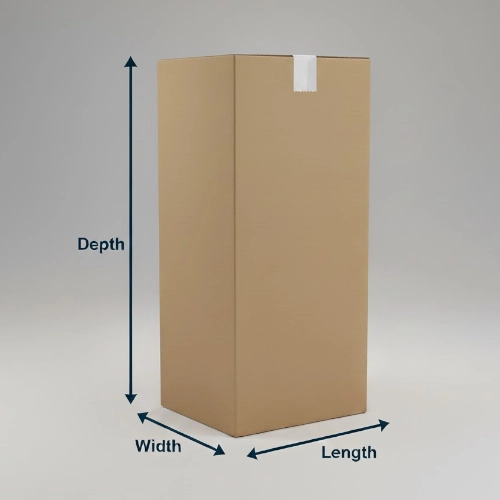

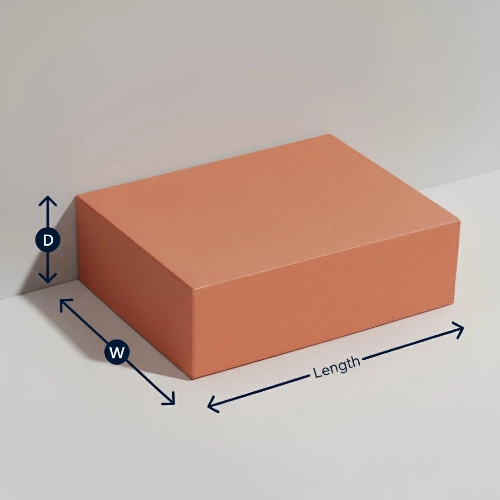

In order to measure the box, you should know the three dimensions of the box, which are: length, width, and depth.

Some companies may use height and depth interchangeably, but the industry standard order of dimensions stays the same. It is length x Width x Depth or Height (L x W x H).

- Length: The longest side across the top when you look down the box.

- Width: The shortest side across the top, perpendicular to the length.

- Depth (height): The distance from the top opening to the base of the box.

In tall or upright boxes, the depth is usually the noticeable measurement, while the length and width are smaller.

In long or flat boxes, the length is the largest, while the depth and width are smaller.

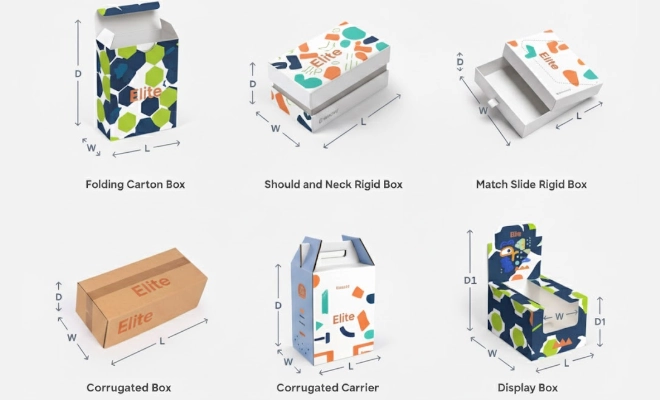

No matter what type of box you choose, it’s important to know the exact dimensions before starting production. Below are some simple examples showing where to find the length, width, and depth of different boxes.

How to Calculate the Volume of a Box

The volume of a box shows how much space is inside it, which is very important for fitting products and planning shipping. To calculate it, you simply multiply the three dimensions of the box:

Volume = Length × Width × Depth

For example, if a box has a length of 10 inches, a width of 8 inches, and a depth of 6 inches, the volume will be:

10 × 8 × 6 = 480 cubic inches

This number tells you the total capacity of the box. Always use the inside dimensions (not the outside) when calculating, since this tells the actual space available for your product.

The Issues of External Dimensions

When measuring a box, using the external dimensions can sometimes cause problems. This is because external dimensions include the thickness of the box material, which does not show the actual space available inside. For example, corrugated cardboard is thicker than paperboard, so the inner space will be smaller than the outer size suggests.

If you only rely on external measurements, products may not fit as expected, especially for custom packaging. This can also affect shipping costs, since carriers calculate dimensional weight based on outer size. Using external dimensions without checking internal space can lead to wasted materials, higher shipping costs, and poor product fit.

How to Measure Box Inserts According to the Product

Measuring box inserts correctly is important to make sure your product fits securely inside the box. Here’s how to do it step by step:

Measure the Product Size

- Take accurate measurements of your product’s length, width, and height.

- For round or irregular shapes, measure the diameter and height.

- These measurements will tell the cut-out size in the insert.

Insert Cut-Out

- The insert cut-out should be slightly larger than the product.

- Add about 1–2 mm of extra space around the product so it fits in easily but doesn’t move around.

Match Insert to Box Interior

- Measure the inside dimensions of the packaging box (not the outside).

- The insert must fit perfectly within these dimensions so it doesn’t move or shift.

- Example: If your box interior is 10 × 8 × 4 inches, your insert should be slightly smaller (e.g., 9.9 × 7.9 × 3.9 inches) to slide in smoothly.

Consider Product Positioning

- Decide whether the product will sit flat, upright, or angled in the insert.

- The cut-out in the insert should align with how the product will be displayed or shipped.

Insert Material Thickness

- Insert materials like corrugated cardboard, paperboard, or foam.

- Make sure the insert thickness supports the product’s weight and protection without reducing the inner space too much.

Test with a Prototype

- Before mass production, test one sample insert with your product.

- Check if it fits securely, is easy to remove, and prevents movement during handling.

Conclusion

Understanding box dimensions is about ensuring consistency across packaging, storage, and shipping. Accurate measurements make it easier for manufacturers, suppliers, and customers. This reduces mistakes, saves time and money, and ensures packaging works well and looks professional.