Rigid stock is a strong, thick paperboard material often used in premium packaging and printing. It is known for its thickness, sturdiness, and long-lasting quality. Unlike regular paper or cardstock, rigid stock does not bend easily and provides a more premium and high-end look. This material is widely used in luxury packaging, book covers, and presentation boxes. Its strength and durability make it important in packaging, printing, and other manufacturing industries.

How Rigid Stock Is Manufactured

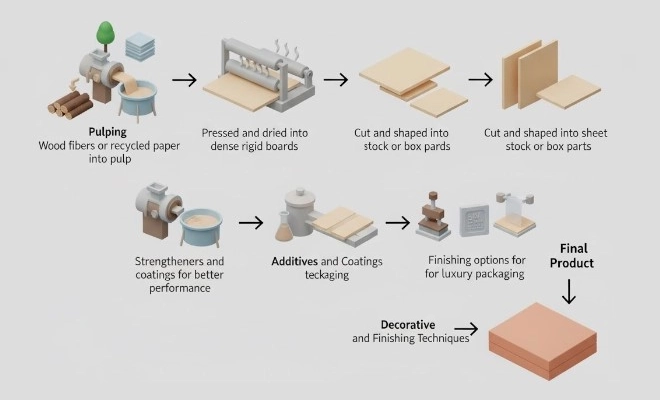

Rigid stock is created through a series of steps similar to paperboard production, but with heavier materials and extra finishing options:

- Pulping:

Wood fibers or recycled paper are broken down into pulp using mechanical or chemical methods. This process separates the fibers so they can be formed into a dense base material.

- Pressing and Drying:

The pulp is formed into thick sheets and pressed to remove excess water. Then the sheets are dried mostly through heated rollers to solidify the material into rigid boards.

- Cutting and Shaping:

Once dried, the rigid sheets are cut and shaped into the sizes and forms, such as sheet stock, boards, or box parts.

- Additives and Coatings:

To improve performance, additives like strengtheners or sizing agents may be mixed into the pulp. Surface coatings are sometimes applied for better print quality, brightness, or barrier properties.

- Decorative and Finishing Techniques:

After the basic board is made, further enhancements can be added. These include foil stamping, embossing/debossing, UV spot finishes, laminations, die-cutting, and special textures. These finishing touches improve presentation and quality.

Types of Rigid Stock

- Duplex Chipboard:

Duplex chipboard is created by laminating two paperboard layers together. It usually has a gray recycled paperboard base and a smooth white coated surface layer. This makes it both sturdy and printable, making it a popular choice for packaging and display boxes.

- Grey Chipboard:

Grey chipboard, also called cardboard or greyboard, is produced by pressing layers of recycled paper together. It provides a rigid, sturdy base that works well for book covers, rigid boxes, and crafts. Its affordability and strength make it one of the most widely used rigid stocks.

- Kraft Chipboard:

Kraft chipboard is made from unbleached kraft pulp, which gives it a natural brown appearance. Known for its durability, strength, and eco-friendly nature, it is commonly used in sustainable packaging. Brands prefer it when they want a rustic and organic look for their products.

- Solid Bleached Sulfate (SBS) Board:

SBS board is created using bleached wood pulp, which makes it strong and pure white.It is lightweight yet strong and allows excellent printing results. Because of its premium look, it is often used for luxury packaging, cosmetics, and high-end retail products.

What is a Rigid Box?

A rigid box, also known as a setup box, is a type of packaging made from thick, strong paperboard. Unlike folding cartons that can be flattened, rigid boxes are pre-assembled and keep their shape. They are sturdy, durable, and mostly used for luxury products like jewelry, electronics, perfumes, and gift items.

Due to their solid structure, rigid boxes offer maximum protection and a premium look. With various options for custom finishes and features, such as foiling, embossing, or magnetic closures.

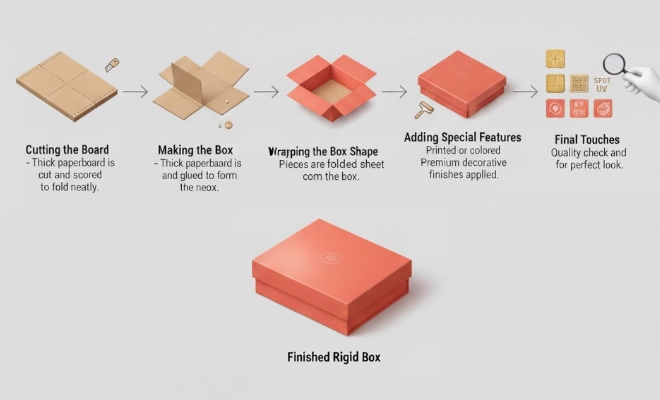

How is a Rigid Box Made?

- Cutting the Board:

Thick paperboard (rigid stock) is cut into pieces and scored so it can fold neatly.

- Making the Box Shape:

The cut pieces are folded and glued together to create the box base and lid.

- Wrapping the Box:

A printed or colored sheet is glued on the outside to cover the board and make it look attractive.

- Adding Special Features:

Extras like foil stamping, embossing, spot UV, or lamination are added to give the box a premium finish.

- Final Touches:

The box is checked for quality, cleaned up, and trimmed for a neat and perfect look.

Types of Rigid Boxes

- Two Piece Box: A two-piece design with a separate lid that fully or partially covers the base.

- Magnetic Closure Box: Features embedded magnets in the flap for a secure and premium closing experience.

- Hinged Lid Box: Comes with a lid attached to the base for easy opening and closing.

- Collapsible Box: Can be folded flat for storage or shipping and assembled when needed.

- Drawer Style Box: Opens like a drawer with a pull-out tray inside an outer shell.

- Shoulder and Neck Box: Has an inner piece (neck) that creates a raised shoulder, giving a luxury unboxing experience.

Conclusion

Rigid boxes make products look high-end and special. They give a good first impression to customers. Brands can design them in many creative ways. These boxes are not just for packaging but also help in branding. Many businesses use them as a packaging and branding tool.